Rocklands Mine

×

Home

The Rocklands Copper mine was only discovered in 2006 despite being in the middle of a rich and historic mining area. Famous old mines in the vicinity include the Great Australia Mine (type locality for Cloncurryite) and numerous small mines around the township of Cloncurry. Little over 120 km due west of Cloncurry, along the National Route 83, is the world-famous Mont Isa mine. Rich copper mineralisation occurs at Rocklands and during evaluation of the prospect, very rich zones of Native Copper were encountered, some of which was beautifully crystallised. UK Mining Ventures (UKMV) negotiated a three month specimen recovery programme with the mine operators CuDeco and this ran between August and October 2017. During this period two UKMV personnel worked in temperatures up to 51°C to recover some of the best crystallised Native Copper specimens found in recent times.

Located approximately 15 km west of Cloncurry township, the Rocklands rich ore bodies were an unexpected discovery in 2006 in an area thought to have been thoroughly prospected. Cloncurry is an old mining town whose origins date back to the 1870s following the discovery of copper in the area. It was built to service the Great Australia mine, a little to the south. Cloncurry is in the county of Cloncurry Shire and is situated towards the western extremity of Queensland and about mid-way with the border with Northern Territory (Figure 1). Cloncurry sits at an elevation of 186 m (610 ft), has mean temperature of 33°C and a population of just over 2,700 (2016). The town can be accessed by road, rail and air; the nearest major conurbation being Mount Isa, 120 km due west. A purpose-built road now connects Cloncurry to the Rocklands mine.

Present day Cloncurry is a busy small township, with all the facilities of such an old mining town in the outback (Figures 2 to 7).

Copper was first discovered in the area by the English explorer Ernest Henry (1st May 1837 – 26th March 1919). While exploring and prospecting in early 1867, his initial discovery heavy black ore samples proved to be iron ore, once analysed in the nearest settlement of Peak Downs. Because of the remote location of the prospect, iron ore was an uneconomic commodity and hence no further investigation was carried out. More by chance however, Henry returned to the area with an Aboriginal boy to look for and collect minerals, and famously on 20th May 1867, discovered the main copper lode which became the Great Australia mine. The town of Cloncurry, from which the mine was serviced, was built about 5 km north of the ore body. The town and mining area have remained prosperous as despite the Great Australia mine having periods of closure, it has frequently been reopened and continues to produce both copper and gold.

Many smaller mines were discovered in the close vicinity of Cloncurry, evidence of which remains preserved to this day. An old headframe is shown in Figure 8, now within the protection of the Cloncurry Unearthed Visitor Information Centre & Museum.

The mining company CuDeco bought property located approximately 15 km west of Cloncurry township in 2005 and it was the following year when Wayne McCrae and the late Tim Koitka discovered the complex of ore bodies that were to become the Rocklands Copper mine. The area had been known as rich producer of copper and gold for well over one hundred years and detailed mapping had already indicated the Rocklands mineralisation. It was McCrae who discovered the prospect’s true potential which has lay hidden beneath the shallow overburden. Why this had been previously missed by modern geophysical and geochemical mapping techniques is outwith this account.

Following the work by Koitka and McCrae, CuDeco undertook an extensive exploration programme, finally characterising 12 orebodies in total. Two of these, Las Minerale and Rocklands South, were found to contain a supergene-enriched zone These are characterised by pervasive coarse Native Copper associated chalcocite ore, resulting in very high-grade orebodies. In addition to geological mapping, geophysics and geochemistry, a comprehensive programme of drilling was completed by which to prove and calculate the ore reserves. Drilling methods included both coring and reverse circulation drilling (RSD). Figure 9 shows a tungsten carbide button bit used for RSD, the circulation nozzles of which have become blocked by sheets of Native Copper; an early indication of the unique mineralisation present.

Reserves having been proven, mine infrastructure was put in place and overburden removal begun. The Rockland Copper mine was now on the map (Figure 10).

The Rocklands mine is situated towards the northern outcropping section of the Mount Isa Inlier of Proterozoic age (2500 to 541 million years ago). The whole region is dominated by a large anticlinal structure (part of the inlier), up to 40 km across, named the Duck Creek Anticline.

Within the anticline south of Rocklands, a sequence of metabasalts, quartzite and jaspilite dominate. Some 5 km NE of Rocklands, a large granite mass, named the Williams Granite becomes the main control on structure and mineralogy.

Pinched between these two geological features is the Rocklands mine, set within a metamorphosed sedimentary sequence of calcareous beds, calc-silicates, siltstone, sandstone/quartzite and quartz magnetite/jaspilite lenses (Table 1), again all of pre-Cambrian age. The mineralised lodes occur within this sequence; structurally controlled to form a series of ESE trending sub-parallel zones and typically associated with steeply dipping dolerite dykes.

| Rock Types | Description |

|---|---|

| Dolerite (diabase) | Mafic rock equivalent to volcanic basalt or plutonic gabbro |

| Jaspilite | Banded iron formation (BIF) with distinctive bands of jasper. A banded mixture of hematite and quartz. |

| Sandstone | Clastic sedimentary rock composed mostly of sand-sized particles |

| Siltstone | Sedimentary rock which has a grain size in the silt range |

| Shale | Clastic sedimentary rock composed of fine-grained particles |

Jaspilite is a chert-like rock rich in iron and is typically found as a banded mixture with hematite and quartz in Banded Iron Formation (BIF). Jaspilite is a chemically precipitated rock and is often an indicator of exhalative chemical sediments or an alteration facies around submarine exhalative hydrothermal vents.

Mining operations commenced in 2015 following the delineation of 12 main orebodies. Two of these, the Las Minerale and Rocklands South contain a supergene-enriched zone of pervasive high-grade coarse Native Copper and associated chalcocite ore. The ore bodies commence near to surface and extend to depths of approximately 140m; orebody widths range up to about 45 m. The overburden, consisting of a weathered surface layer is between 15 to 20m deep.

Specimen recovery was primarily from the Las Minerale open pit, pictured in Figure 12. The image (courtesy of CuDeco) has been annotated to indicate the approximate position of the low angle reverse fault that traverses the pit. The downthrow side is rich in sulphides, namely Pyrite and Chalcopyrite and the up-throw side forming the oxide zone, rich in Native Copper and gradually grading to Chalcocite towards the north. Aligned along the fault is a transition zone of Chalcocite and Bornite separating the sulphide and oxide zones.

The basic geology of the supergene-enriched zone is set-out in Figure 13 and shows the original pre-weathered outcrop and the orebody as it is today with the position of the open pit.

A key element to supergene-enrichment is the position of the water table, about which ore concentration processes focus. The main (central) sketch labelled “Rocklands geology and ore concentration” (Figure 13) depicts a water table which changes markedly in depth below the ground surface. This surface is not controlled by rock type; i.e. the steeply dipping metamorphosed sandstone-siltstone bodies and dolerite dykes, as might be expected, but varies as a function of permeability, porosity and mineral grain size; the latter controlling capillary pressure effects above the free water level. Because of this, varying water saturations and structural controls, the enriched zone is complex across full extent of the twelve orebodies.

Classification of the Rockland’s orebodies is not as straight forward as it would first appear, given the age of the deposit, a significant period of Earth history has elapsed since the ore was emplaced. In the case of the Las Minerale and Rocklands South ore bodies, it is obvious that supergene-enrichment accounts for the zone of secondary enrichment (Figure 13); the zone which has produced the spectacular Native Copper specimens recovered during this project. The Las Minerale body alone has a combined native copper/supergene zone strike length of circa 1200m. However, supergene processes only account for the concentration of elements in more recent (post-late pre-Cambrian) geological time and certainly post-Great Oxidation Event (GOE) that occurred in the Paleoproterozoic Era, the first of the three eras of the Proterozoic Eon.

The original source of the metallic elements is potentially associated with the north-west intrusive system, mainly characterised by dolerite dykes. However, due to the presence of gold and cobalt minerals, current investigative work includes three other possible candidates as set out in Table 2. As the research continues, new theories or confirmation of specific ore emplacement mechanisms will be updated on this site.

| Classification Type | Controls |

|---|---|

| Intrusive Related Gold System (IRGS)? | Typically regional in scale, structurally controlled - repeats Iron Oxide Copper-gold System (IOCG)? |

| Iron Oxide Copper-Gold System (IOCG)? | Tick-hill style (Mount Isa Mines) - structural controlled shear zone in Corella Formation |

| Gold Skarn System? | Potentially associated with the north-west intrusive system |

A relatively small number of mineral species have been found at the Rockland Copper mine; these are listed in Table 3 together with their chemical composition. The non-economic minerals (gangue minerals) are listed in Table 4. The chemical composition of the complex gangue minerals Actinolite and Biotite is variable hence formulas are different from different sources. Those in Table 4 are taken from Mindat and do differ slightly from Fleischer (Back, 2014).

| Mineral Species | Chemical Formula | Word-formula |

|---|---|---|

| Azurite | Cu3(CO3)2(OH)2 | Copper carbonate hydroxide |

| Bornite | Cu5FeS4 | Copper iron sulphide |

| Chalcocite | Cu2S | Copper sulphide |

| Chalcopyrite | CuFeS2 | Copper iron sulphide |

| Cobalt minerals | Co | Cobalt sulphides |

| Copper (native) | Cu | Copper |

| Gold (native) | Au | Gold |

| Magnetite | Fe2+Fe3+2O4 | Iron oxide |

| Malachite | Cu2(CO3)(OH)2 | Copper carbonate hydroxide |

| Pyrite | FeS2 | Iron sulphide |

| Mineral Species | Chemical Formula | Word-formula |

|---|---|---|

| Actinolite | {Ca2}{Mg4.5-2.5Fe0.5-2.5}(Si8O22)(OH)2 | Calcium magnesium iron silicate hydroxide |

| Biotite | K(Fe2+/Mg)2(Al/Fe3+/Mg)([Si/Al]Si2O10)(OH/F)2 | Potassium magnesium iron aluminosilicate hydroxide |

| Calcite | CaCO3 | Calcium carbonate |

| Quartz | SiO2 | Silicon oxide |

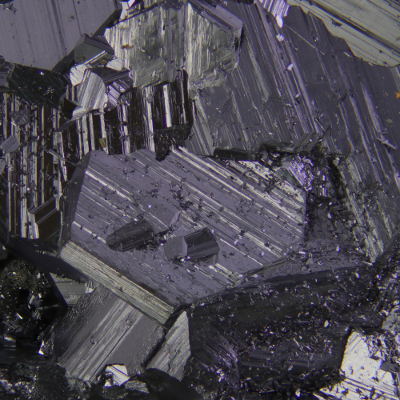

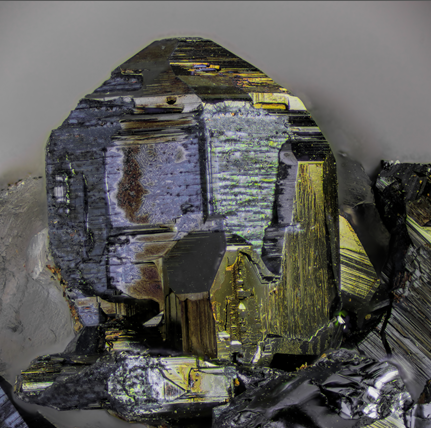

Examples of some of the mineralisation are shown in Figures 14 and 15.

The choice in the method of the extraction of any ore body is dependent on the thickness of overburden; i.e. the layer covering the ore body formed from post-ore emplacement rock deposition and near-surface weathering. In the case of an open pit, all the overburden overlying the ore deposit obviously must be removed. However, as the pit deepens, a stable slope needs to be maintained to prevent the side of the pit collapsing, and so ever larger volumes of overburden need to be removed extending outwards from the pit. The volume of waste rock (overburden) to that of ore is termed the stripping ratio and this determines whether the ore is mined by open pit or underground development.

The ore deposits at Rockland are very near to surface and so the stripping ratio is vastly in favour of an open pit operation. Typically, an overburden depth of 15 m to the thickness of ore at about 125 m, giving a waste to ore ratio of roughly 1:8. The simple sketch shown in Figure 16 illustrates the relationship of the open pit stepped benches to the vertical changes in mineralisation. This is diagram is not to scale. Its also shows how the ratio of bench height to bench wide will affect the slope angle between surface and the pit bottom. The open pit is shown in Figures 11 and 17.

The slope angle of the open pit’s sides is engineered by the width to height ratio of the stepped benches. This angle is determined by slope stability analysis, a methodology that analyses all factors which influence the stability of the slope. Ideally the slope would be vertical as this would constrain the volume of removed overburden to that of the plan area of the ore body. Any departure from vertical required ever increasing volumes of overburden to be removed, so changing the stripping ratio and hence the economics.

Practically, vertical pit faces are not possible at Rocklands due to the variable rock strength; structural dip; brecciation; faulting; fractures; rock mass fracture system and the influence of water on frictional sliding. Despite the present-day arid climate in this part of Queensland, the Cloncurry region does still have an annual rainfall of around 510mm (20.1 inches).

Once design of the open pit is the most complex part of the operation in order to maintain slope stability, maximise the economics of the stripping ratio and provide safe and stable roadways between surface and all operational areas. The mining methods are standard and require no explanation here. Bench sections drilled and blasted (Figure 18); broken ore (or waste) loaded into 140 tonne dumper trucks (Figure 19) and hauled (Figure 20) to the stockpiles ready for processing. Large sheets of Native Copper cannot pass through the primary jaw crusher due to its malleability; such sheets would just disform and block the crusher. Run of Mine (ROM) ore, i.e. mined and ready to go to the processing plant, is inspected and large sheets removed by excavator (Figure 21).

UK Mining Ventures and CuDeco negotiated a specimen recovery programme that ran for almost three months during August to October 2017. These are the winter and spring months in Australia and collecting was constrained by onset of Australian summer. Even in spring, temperatures at the bottom of the Las Minerale open pit attained 51°C, a temperature permitting a maximum working period of only 30 minutes. For miners operating heavy equipment such as drilling rigs, excavators, dump trucks and dust suppressor units, their cabins are air conditioned. Geologists and specimen collectors require the hands-on approach and so must endure these temperatures, albeit for very short durations! Two UKMV personnel were on site for the whole of this period and the first collector-grade specimens were recovered in August 2017.

Unfortunately, the upper oxide zone had been mined long before the arrival the UKMV team and only odd the remnant specimen was found. Specimen recovery was not straight forward by any means due to many constraining factors: variations in ore mineralogy, modern mechanised mining.

The many significant finds are described later.

Monday 17th June 2019

The Rocklands Copper mine is currently non-operational until further notice. This has come about due to difficulties encountered in the mineral processing plant with respect to the large volumes of native copper and the complex nature of the ore.

UK Mining Ventures still maintain an excellent inventory of Native Copper specimens, most of which are beautifully crystallised. Please contact us for more details.

This section is a repository for information and photographs taken over the past two years which document the mineral treasures of the Rocklands mine.

There are two photographic archives: Photo Archive 1: Specimen Treasures of Rocklands Copper Mine and Photo Archive 2: Cloncurry and Rocklands Copper Mine. These contain a wide selection of photos and will be added to whenever new material becomes available.

Copyright © 2021 UK Mining Ventures Ltd